I created several projects with EPS8266 wifi modules.

The small cheap ESP01 module has only a few IO pins so i did not used it until now.

In one of my recent Aliexpress China orders i also added a small cheap ESP01S module to my shopping list. I also ordered some boards to easy test and use of this module: ESP01 has 2x4 pins close to each other.

Not easy to use on a breadboard therefore i also added to my shopping list.

(Right to left. [First is the ESP01 module itself] )

- ESP01 - Breadboard interface.

- ESP01 - TTL interface

- ESP01 - USB interface

My plan was to use the ESP01 - USB interface board to program an test the ESP8266 module.

Then the disappointment : to program the small ESP01 module you need to pull GPIO0 to ground. My cheap interface USB module has no jumper or switch to do that!

A reset button would also be nice.

And perhaps easy access to all the pins to experiment.

If i would use the TTL interface wired this to a USB TTL / RS232 (FTDI) interface cable i would have the same problem.

An option would be start from zero, using a breadboard interface, and make my own interface.

(Later i found there are some ESP01 USB modules with programming switch. I did not find one with programming switch and reset button!)

|

| ESP01 with USB Module |

But what is the use of these cheap "ready to use" interfaces. For programming, testing and debugging

I decided to make my "ESP01 Break-in board". A board to put between the ESP01 and the boards with the 2*4 connector.

(I decided to call it "Break in board". It is not a "Break out board" to use and get access to chip pins but a "Break in" to put between the existing connections to add features.)

It needed (minimal) a programming switch, a reset button and access to the pins.

Later on i decided to add also some additional features. (See photo, final specs/feature list below.) This are additional features but not really needed.

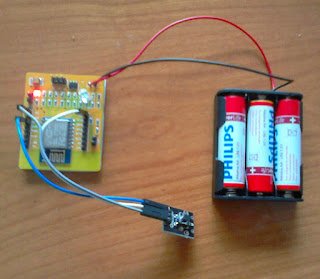

I used a small double Side Prototype PCB Bread board Tinned Universal 20x80 mm FR4 28*6 holes.

|

ESP01 "Break in board"

with EPS and USB

connected. |

(All holes are plated through).

I added pins to fit in a 2*4 pin connector (on bottom) and additional 2 times 4 pins to get easy access to all pins and a female 2*4 connector for the ESP01 module (on the top).

On my (current) laptop free USB connectors are at the left side. I wired my "Break-in board" with this in mind. (USB connector pointing to the right when using this board).

Mark on the PCB with an arrow the direction of the ESP01 module.

A push button is used for the reset, (Bottom of the PCB) wired to ground and reset.

While uploading a program i do not want to continuously press a button. I decided to use a small slide switch (Top).

In stock i had a three position switch. If you have a small two position slide switch you use that.

The three position switch i used has 6 pins: (and two shield pins)

Left no pins are connected

Middle pin 1 and 4 are connected ' / pin 3 and 5 connected "

Right pin 1 and 4 are connected '

Pin 2 and 6 have no use (n.c.), i did bend them away and soldered the switch on the PCB.

I decided to use the middle position as programming position and wired pin 2 and 5 ' to ground and GPIO0.

|

| 3 position switch |

At this point my basic minimal "ESP01 Break-in board" was ready.

|

| ESP01 "Break in" board. (top view) |

On my board i also added some other things i had in stock:

- 6 female pins connected to to ground (and next to it a)

- 25 Points Mini Solderless Prototype Tie-point Breadboard

- A micro switch (three pins Common, Normal open, Normal closed ) with connections to pins

to easy wire them for experiments. (on bottom next to reset pushbutton).

- Passive electromagnetic impedance 16 ohm AC buzzer/2KHz 3V 5V universal buzzer (- connected to ground, other side to a pin and 100 ohm resistor with a second pin.

-

On my slide switch at pin 1 and pin 4 ' contacts available are (Left open, Middle and Right closed), i wired them to two pins on the PCB.

The condensator on the ESP01 - USB interface board comes very close to PCB. Some insulation tape was added. As a final touch i used cable ties to join some cable bundles.

|

| ESP01 "Break in" board (bottom view) |

RESULT:

"ESP01 Break-in board":

Switch for programming the ESP01,

Reset button,

Easy access to all pins of the ESP01.

Some additional switches.

A mini buzzer (One side connected to ground. Connect the other side e.g. with a Dupont cable to GPIO2)

Mini solderless prototype board for additional components/experiments.

|

| ESP01 "Break in" with ESP01 and USB (bottom view) |