I did buy this electricity measure Smart control programmable equipment on AliExpress

I expected this device would be controllable via WiFi, however unfortunately no. It can be controlled using the buttons on the device, via bluetooth and also via IR remote control.Manual

| EN | CN |

Review and additional info

As you can read above the manual is somewhat difficult to understand.

On the back side are connectors for the power input. The bottom can stand on your desk or some screw can be used to fixate it at the wall. Is is important to put some tape on the connectors that is not used for protection.

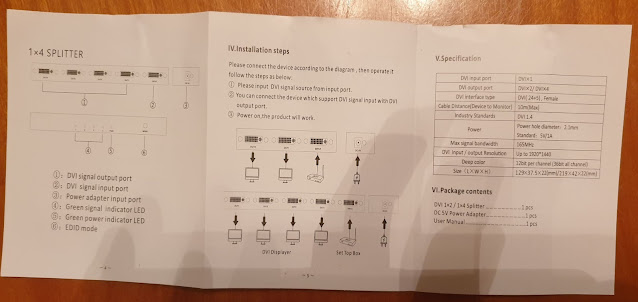

According to the schematic in the manual when using the screw connectors on the back ground is NOT connected !

Safety could be improved by changing the hardware design and add a plastic cover that can be moved to cover one of the the two connectors.